Overview

The SC-Packaging module in PriceCal is developed in collaboration with Pacdora, a professional online 3D packaging design platform.

With SC-Packaging, you can not only select from a wide range of box styles and models (such as Double Tuck End Box, Snap Lock Bottom Box, etc.), but also design your packaging directly online using Pacdora’s integrated Design Studio.

This integration enables you to:

-

Browse and choose from hundreds of ready-made 3D packaging models

-

Instantly preview packaging structures in 2D and 3D views

-

Customize artwork online with Pacdora’s design tools before printing

-

Streamline your production workflow by linking design, structure, and pricing seamlessly

💡 Best for: printers and packaging businesses who want to offer customers a full packaging solution — from box selection to online design and instant quotation, all in one platform.

💡 Note: SC-Packaging is available for PriceCal Elite users only.

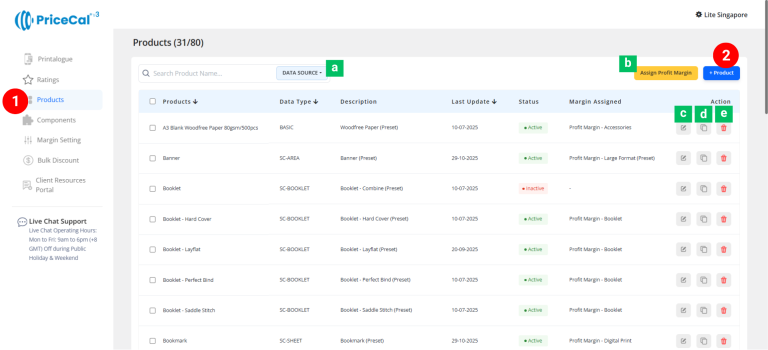

🧭 Navigating to SC-Packaging Product Creation

-

Go to your Product Dashboard.

-

Data Source Sorting [a] – Filter to view products from the same data source.

-

Assign Profit Margin [b] – Apply one profit margin setup to multiple products at once.

-

-

To create or manage a product, click Add Product – Start a new SC-Sheet product setup.

-

Edit [c] – Modify existing product details.

-

Duplicate [d] – Clone an existing product setup to reuse its structure.

-

Delete [e] – Remove unused or outdated products.

-

🧱 Create a SC-Packaging product

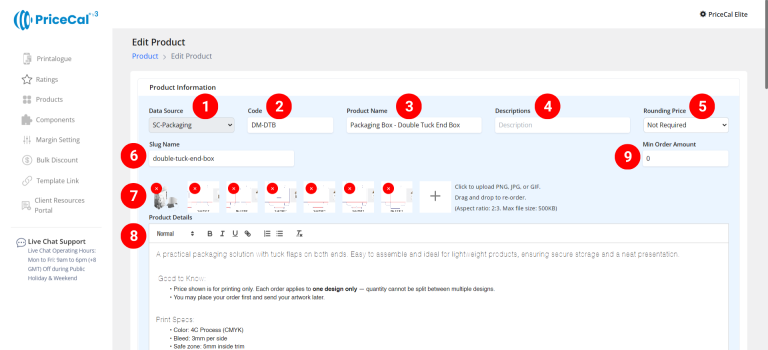

Step-by-Step Setup

-

Select “SC-Packaging” as your product source.

-

Enter a unique code (up to 8 characters).

-

Input your Product Name, e.g., Packaging Box – Double Tuck End

-

Add a short Description to identify production type. Example: “Own Production”, “Outsource Production”

-

(Optional) Choose your Rounding Price— round price up/down to achieve integer pricing.

-

Enter a Slug Name to create a product link.

Example: Slug “double-tuck-end-box” → your link will be

https://lite.printmart.cc/products/double-tuck-end-box

If no slug is specified, a random code will be used. -

Upload Product and Packaging Model Images (up to 10).

-

Fill in your Product Details and Specifications, such as product, print specs, and production days.

-

(Optional) Set a Min Order Amount.

💡 Tip: Regardless of the print quantity or total price, there will be a minimum charge unless the calculated price exceeds the minimum order amount.

-

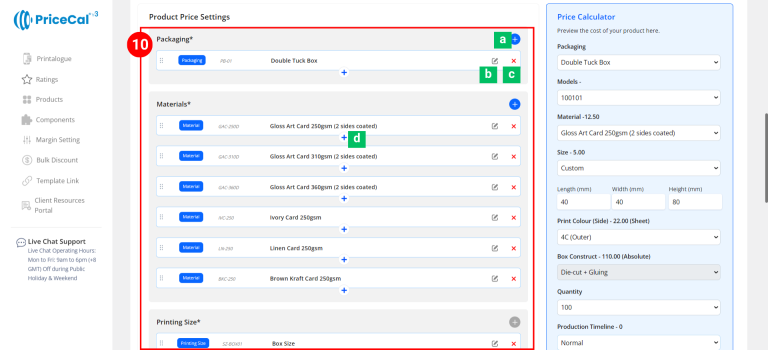

Assemble Product Components. Each product in PriceCal is built using multiple components.

Add and organize your components under the Component Section.- Add Component [a]:Click to add or create a new component for this product.

-

Edit [b]: Modify component setup (changes sync to all products using this component).

-

Delete [c]: Remove the component from the current product.

- Add Nesting Component for Material [d]: Add sub-components under a main one. Example: Add “Lamination” under “310gsm Art Card” so it only appears when that material is selected.

🔹 Required and Core Components

These must be included for every SC-Packaging product:

-

- Packaging – Add the packaging component you created.

-

Material – Define the printing material (e.g., 310gsm Art Card, 128gsm Gloss Paper).

-

Printing Size – Set product print size.

💡 Note: If the open size of your packaging or box model exceeds the Max Material Print Area, the system will stop the customer from proceeding to the next selection (printing cost, or finishing). -

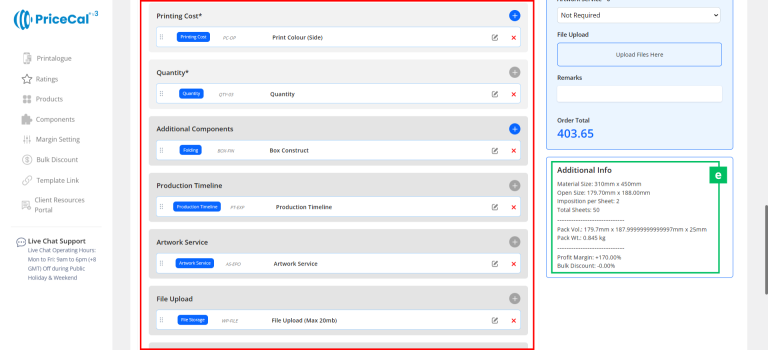

Printing Cost – Configure Printing side and cost

-

Quantity – Define customer-selectable quantities.

🔸 Optional System & Custom Components

Add these depending on your product requirements:

-

-

Additional Component – Finishing options such as Lamination, Cutting, Finishing.

-

Production Timeline – Offer flexible production speed (Normal / Next Day / Same Day).

-

Artwork Service – Design or setup service options if applicable.

-

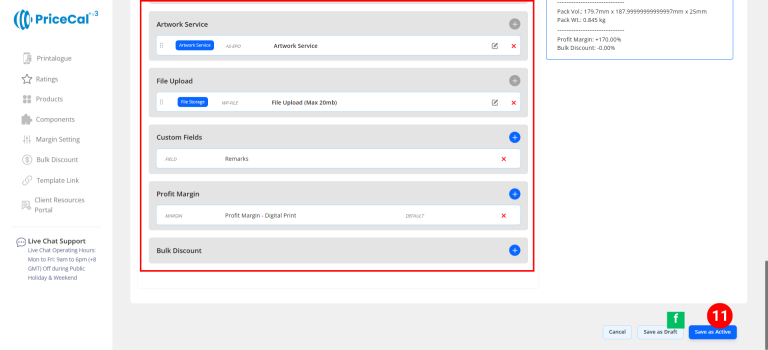

File Upload – Enable file upload and select storage location (WordPress or Dropbox). [Only displayed after integration into WordPress website]

-

Custom Fields – Collect extra info or artwork links (e.g., Google Drive link, ).[Only displayed after integration into WordPress website]

-

Profit Margin – Apply different profit percentage levels.

-

Bulk Discount – Automatically apply discounts for large orders.

-

🧾 Additional Info [e]: Get instant calculation insights

-

- Printing Parameters – Shows nesting type, material size, Imposition per Sheet, and Total Sheet.

-

Package Overview (est.) – Calculates estimated volume and weight based on GSM, thickness, and quantity.

-

Financial Overview – Displays applied profit margin and bulk discount summary.

11. Finalize the Product

After setting up all details and components:

-

-

Click “Save as Active” to publish the product to your storefront.

-

(Optional) Click “Save as Draft [f]” to keep the product inactive and hidden from the shop until ready.

-

💡 Best Practices & Tips

-

Choose consistent packaging models — ensure each component matches the same category (cannot mix models).

-

Upload both 2D and 3D packaging previews to improve clarity for customers.

-

Use “Own Production” or “Outsource Production” tags for quick product identification.

-

Always add a minimum order amount to prevent underpriced low-volume orders.

-

Apply Profit Margin & Bulk Discount to maintain stable profit margins across order sizes.

-

Use Nesting Components to link finishing options (e.g., Lamination only appears under specific materials).

-

Test calculations before publishing to ensure your pricing structure works correctly.

-

Save time with duplication — once a box model is set up, clone it and edit details for faster new product setup.