📦 Setting Up Box Component (SC-Box)

The Box component is designed for printers who cut and produce their own box packaging.

Unlike SC-Packaging, which connects with Pacdora for ready-made models, online design tools and download packaging dieline, SC-Box uses our provided box formulas to calculate the open size (die-cut layout) for cutting and printing.

This lets you create fully customized box models — perfect for local production or specialty packaging with in-house cutting machines.

Note: SC-Box is provided online design tools and download packaging dieline function. This formula is only used to calculate the open box size to obtain the printing price.

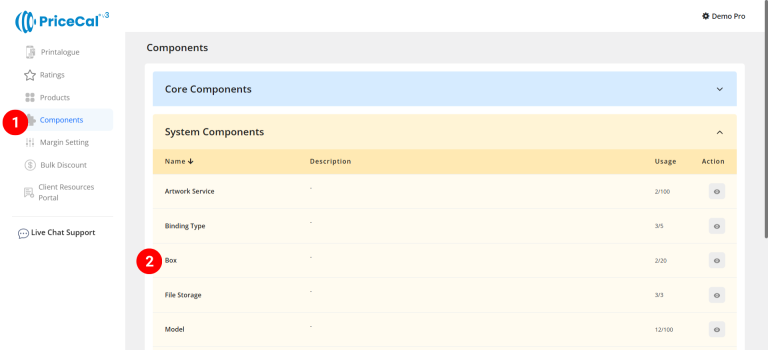

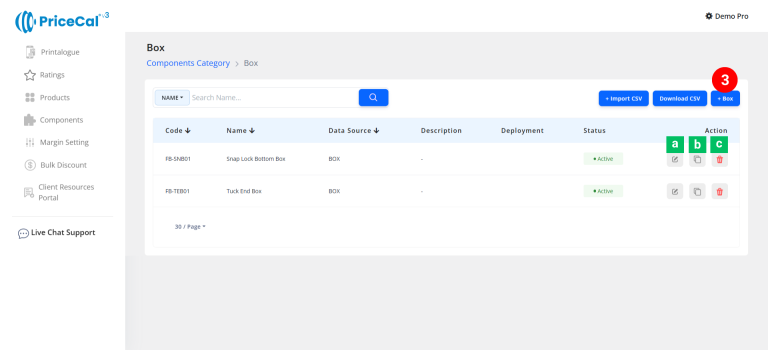

🧭 Navigating to Box Setup

- Go to Component dashboard

- Click Box category

- Add Box

Edit [a]: modify existing components.

Duplicate [b]: clone a component setup to reuse and create new.

Delete [c]: remove unused component.

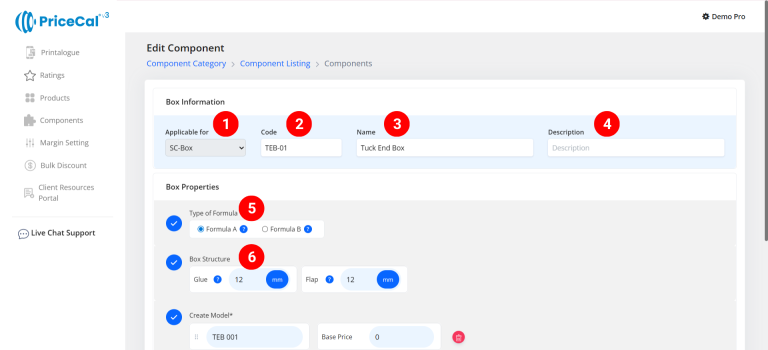

🧱 Create a Packaging Component

Step-by-Step

- select “SC-Box”

-

Put a unique code (up to 8 units) 💡 Example: BFA001 (for Formula A)

-

Enter a descriptive name for the packaging model. 💡Example: “Double Tuck End Box,” “Snap Lock Bottom Box,” or “Mailer Box.”

- Add a short description to help you recognize the packaging type easily.(Descriptions help team members quickly identify model use cases and box functionality, Example “Standard box with double tuck ends — suitable for small products.”)

-

Choose your preferred Box Calculation Formula from the list.

PriceCal’s SC-Box engine provides built-in formulas to automatically calculate open-size layouts based on your entered 3D box size.

You can also create custom box models (e.g., window boxes or specialty box designs)

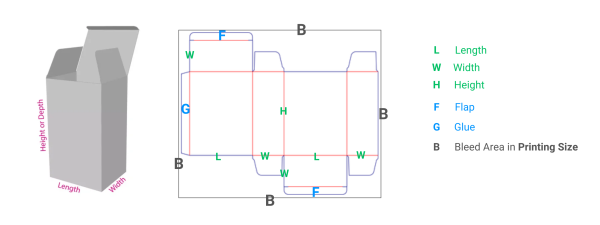

💡 Example box styles can be referred from Pacdora- Formula A: Common for Double Tuck End or Standard Folding Cartons.

Open Width Size = Glue + 2*Length + 2*Width + 2*Bleed

Open Height Size = 2*Flap + 2*Width + Height + 2*Bleed

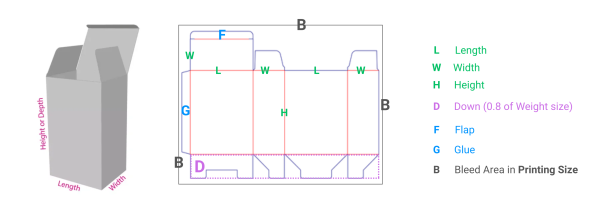

- Formula B: Suitable for Snap Lock Bottom or Crash-Lock Bottom designs.

Open Width Size = Glue + 2*Length + 2*Width + 2*Bleed

Open Height Size = Flap + Width + Height + Down (0.8*Width) + 2*Bleed

- Formula A: Common for Double Tuck End or Standard Folding Cartons.

-

In Box Structure, enter the Glue and Flap section size. 💡 Tip: Standard size is 12 mm for both glue and flap sections.

-

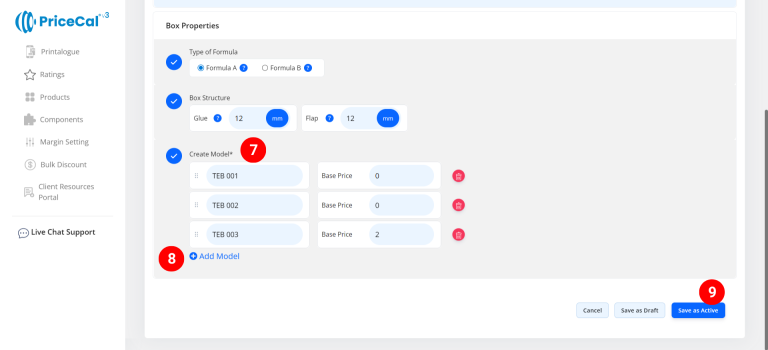

Enter your Box model information

– Model Name: The name of the box model customers will see (e.g., “TEB 001,” “Model A001”).

– Base Price: The one-time startup or die-cut setup cost applied per model. -

Add box model if you have other model available for your customers to choose from

- Click “Save as Active” to finalize your box model configuration.

💡 Best Practices & Tips

-

Best for: Printers who produce and cut packaging boxes in-house.

-

SC-Box gives you control to define your own cutting and folding logic.

-

Keep your formula inputs accurate (glue, flap, bleed) for proper layout calculations.

-

If you want pre-built 3D models and online design tools, use SC-Packaging (Pacdora) instead.

-

Test each model by generating a few open-size layouts to confirm the cutting size is correct.

✅ Next: Configure Printing Size and Additional Component

After completing your Box Model Setup, the next step is to define printing sizes and finishing options (Die-Cut+Glue)

This ensures your packaging products are fully ready for quoting, ordering, and production.